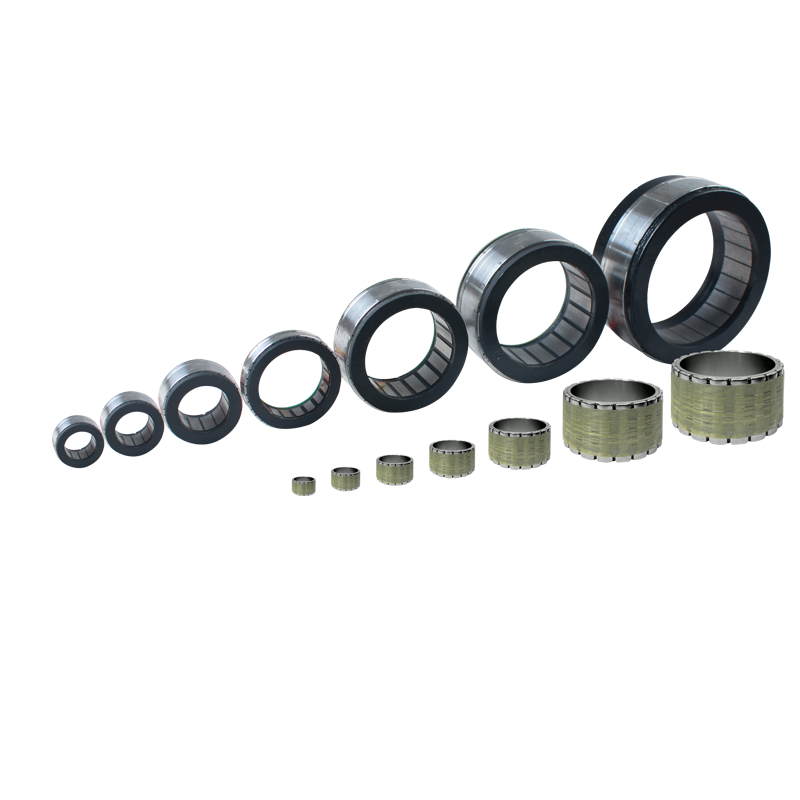

When selecting a stepper motor for industrial applications, choosing the right stepper motor sizes is essential for optimal performance and efficiency. Stepper motors are available in various frame sizes, each offering different torque, speed, and precision characteristics. At Leadshine, we provide a wide range of stepper motor sizes including NEMA 8, 11, 14, 16, 17, 23, 24, 34, and 42. This allows businesses to select the appropriate motor to match the requirements of their machinery and automation systems.

Smaller stepper motor sizes, such as NEMA 8 or 11, are suitable for compact equipment where space constraints are critical. Mid-range sizes like NEMA 17 and 23 are commonly used in CNC machines, 3D printers, and robotics, providing a balance between torque and precision. Larger sizes such as NEMA 34 and 42 are often applied in heavy-duty industrial machinery that demands higher torque and load capacity.

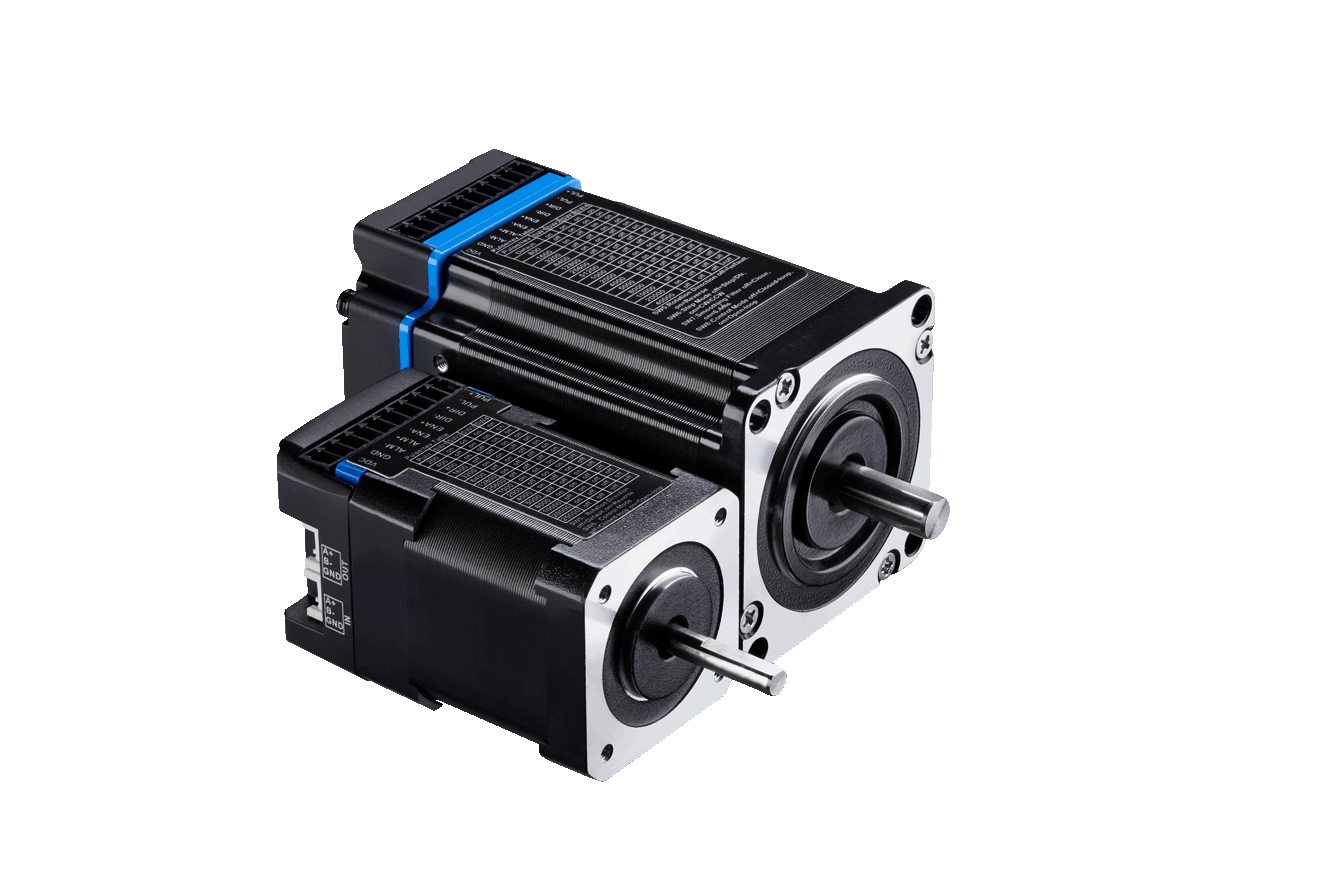

Advantages of Integrated Stepper Motors

Leadshine's integrated stepper motor solutions simplify installation and system design by combining the motor and drive into a single unit. Integrated stepper motors reduce the number of components and minimize wiring requirements. This compact design saves space and reduces installation time, while also lowering overall system costs.

Our integrated stepper motors are available in popular frame sizes NEMA 17, 23, and 24. These motors incorporate high-performance digital stepper drives, delivering precise motion control without the need for additional external drives. This integration ensures reliable operation and consistent performance, making it easier for businesses to deploy stepper motors in automation projects.

Selecting the Right Stepper Motor Sizes for Your Application

When choosing stepper motor sizes, several factors should be considered. First, evaluate the torque and load requirements of your application. Mid-range sizes like NEMA 17 or 23 often provide sufficient torque for a wide range of tasks. Next, consider the available installation space. Integrated stepper motors can help overcome space constraints by combining motor and drive into a single unit. Finally, review the required precision and speed. Stepper motors deliver precise control over movement, and the right size ensures optimal efficiency and minimal vibration.

Leadshine offers detailed technical specifications for all our stepper motor sizes, helping businesses identify the ideal motor for their applications. With options spanning small to large frame sizes, our solutions can support everything from compact automated systems to industrial machinery.

Conclusion

Choosing the right stepper motor sizes is crucial for achieving reliable and efficient motion control in industrial applications. Leadshine provides a comprehensive selection of stepper motors and integrated stepper motors designed to simplify installation and optimize performance. By considering torque, space, and precision requirements, businesses can select the appropriate stepper motor sizes to meet their specific needs. Our integrated stepper motors combine high-performance drives with reliable motors, helping streamline automation systems and reduce complexity.